Biomere avoid micro plastics

Up to 100 % bio-based Products

Same performance and properties as non-degradable polymers

Biodegradability adapted to specific final product

Delivery forms tailored to application

To Product Search

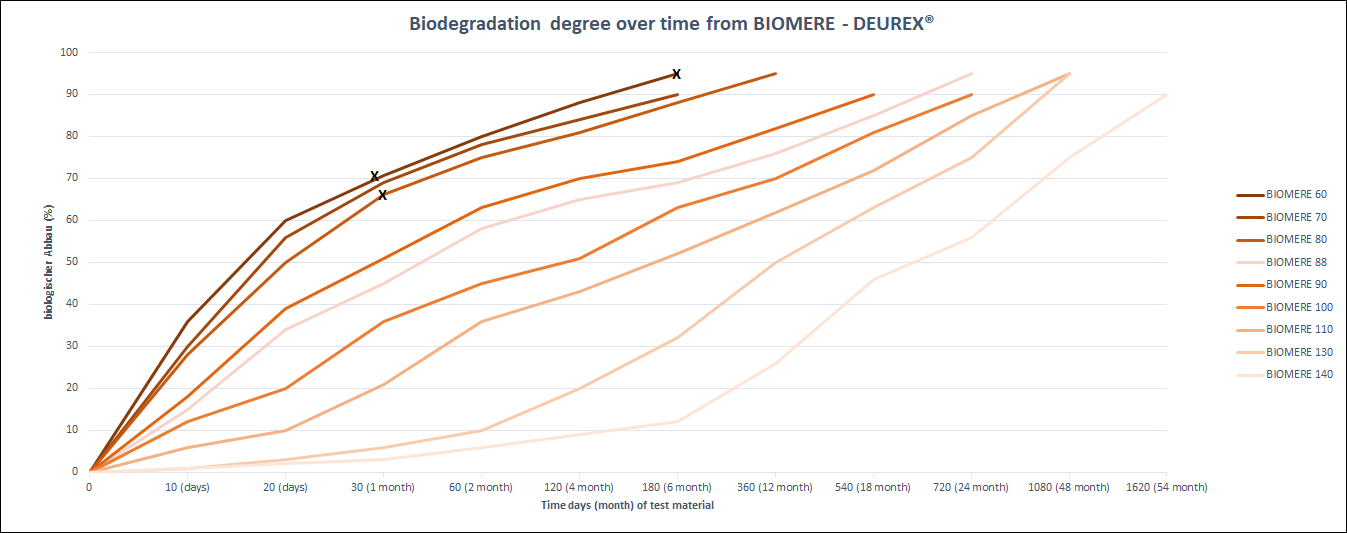

We have a wide range of different BIOMERE at our disposal. As usual, we offer you optimum surface properties without burdening the environment. You decide the period of biodegradability, the desired properties, the melting range and the delivery form.

Certified Biodegradability

We can specifically control the period of time that it takes for BIOMERE to biodegrade.

Each application has very specific requirements for this period of degradation.Therefore, this period can be adapted to the life cycle and requirements of your product.

For an example, we guarantee a time to biodegradability of 30 days for citrus fruits and 48 months for fertilisers (EU 2019/1009).

BIOMERE consist of natural lipids and natural paraffins and as such are a food source for numerous bacteria and fungi. BIOMERE are stable in a dry and bound state. Biodegradation processes only begin when phosphates, nitrogen, heat, salts and, above all, moisture allow such fungal and bacterial cultures to grow. Such conditions are found in soils, compost and especially in the aquatic environment, but not under normal conditions. For this reason, BIOMERE can be kept for a long time outside the aquatic environment.

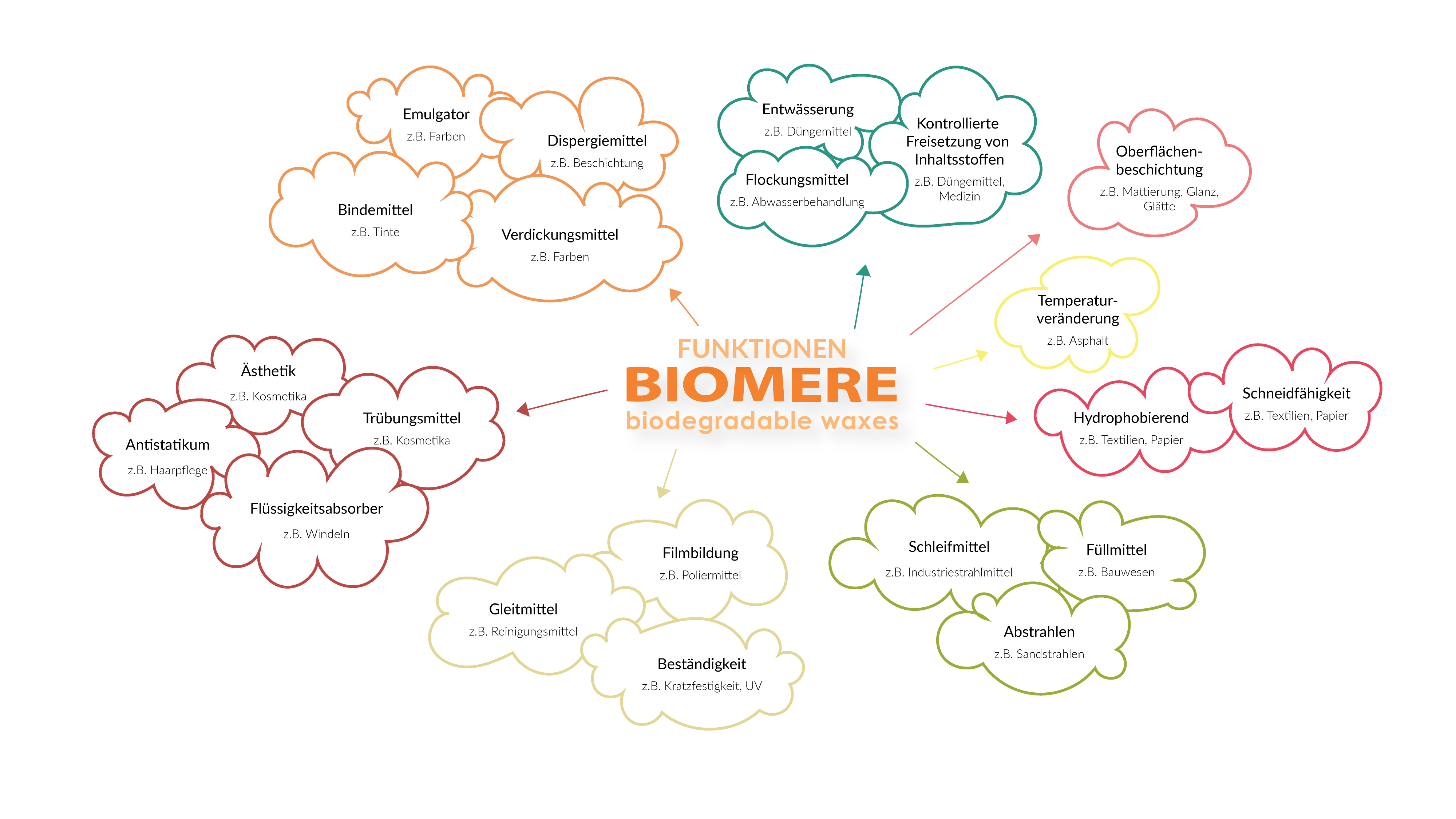

Functions

BIOMERS perform at least the same as conventional polymer additives or waxes with the difference that they do not burden our environment.

Through the use of BIOMERE they achieve required properties, such as:

- Surface properties (scratch resistance, matting, gloss)

- Resistance (UV, water, heat, frost).

- Binding agents, dispersing agents or lubricants, etc.

Here you will find the perfect BIOMER for your application.

Applications

BIOMERE are the substitute for polymer additives and perform at least the same as conventional plastic additives. Aus diesem Grund kommen BIOMERE für eine Vielzahl unterschiedlicher Industrien und Anwendungen in Frage, wie zum Beispiel: Dünge-und Pflanzenmittel, Reinigungs- und Pflegemittel, Druckfarben und Lacke, Sinter/Pulvermetalllurgie, Textilien, Kosmetika, Klebstoffe.

Melting Range

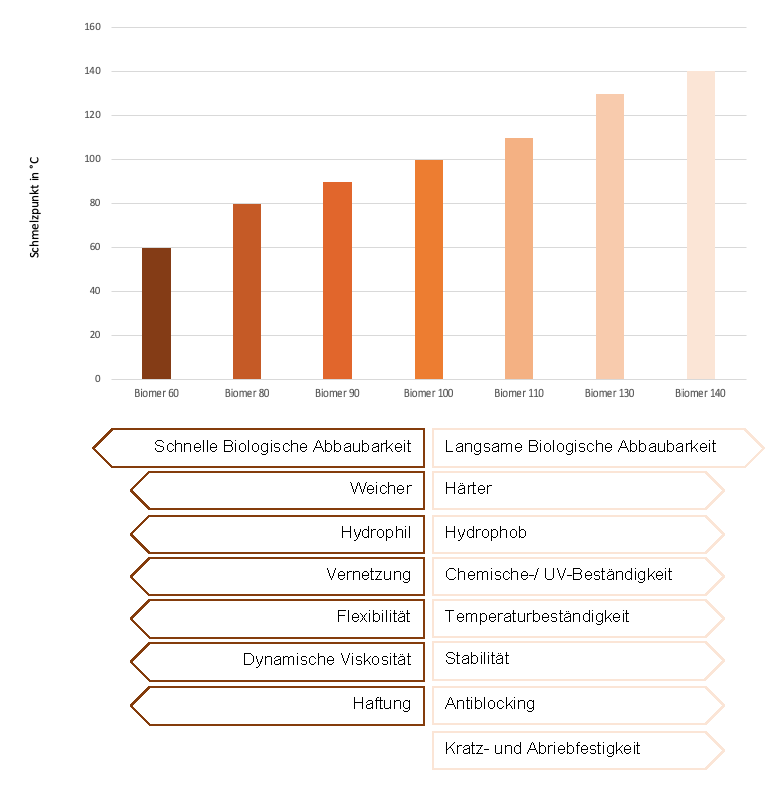

Each application has a preferred melting range, as well as a desired delivery form.

We therefore offer the full range of delivery forms and melting properties (60°C-140°C) - from micronised powder to coarse and fine granules to oily or aqueous dispersions as well as emulsions.

Avoid Microplastics!

Every year in Europe alone approx. 213.300 tons

of microplastics are are directly and deliberately released into nature!

This corresponds to the amount of plastic of

59.000.000.000 Plastic bottles (ECHA 2019)

Customised Biodegradability!

You decide how fast you want your perfect BIOMER to biodegrade.

In this way, you avoid unnecessarily used microplastics and do your bit for our environment.

Functions of BIOMERE

To Product Search

Find Your Perfect BIOMER

Biomere perform at least the same as conventional additives without creating microplastics! Choose your perfect biomer based on melting point and desired property.

A BIOMER 60 has a low melting point (60°C), tends to be soft and flexible, and degrades relatively quickly.

A BIOMER 140, on the other hand, has a high melting point (140°C), is very hard, inflexible and very durable - but degrades slowly.

Due to our high level of expertise and many years of experience, we are able to find the perfect BIOMER for your application and will be happy to advise you.

Applications

BIOMERE are the substitute for polymer additives . For this reason, BIOMERE are suitable for a wide range of different industries and applications.

Below you can learn more about the industries in which you can avoid the creation of microplastics by using BIOMERE.

Biomere

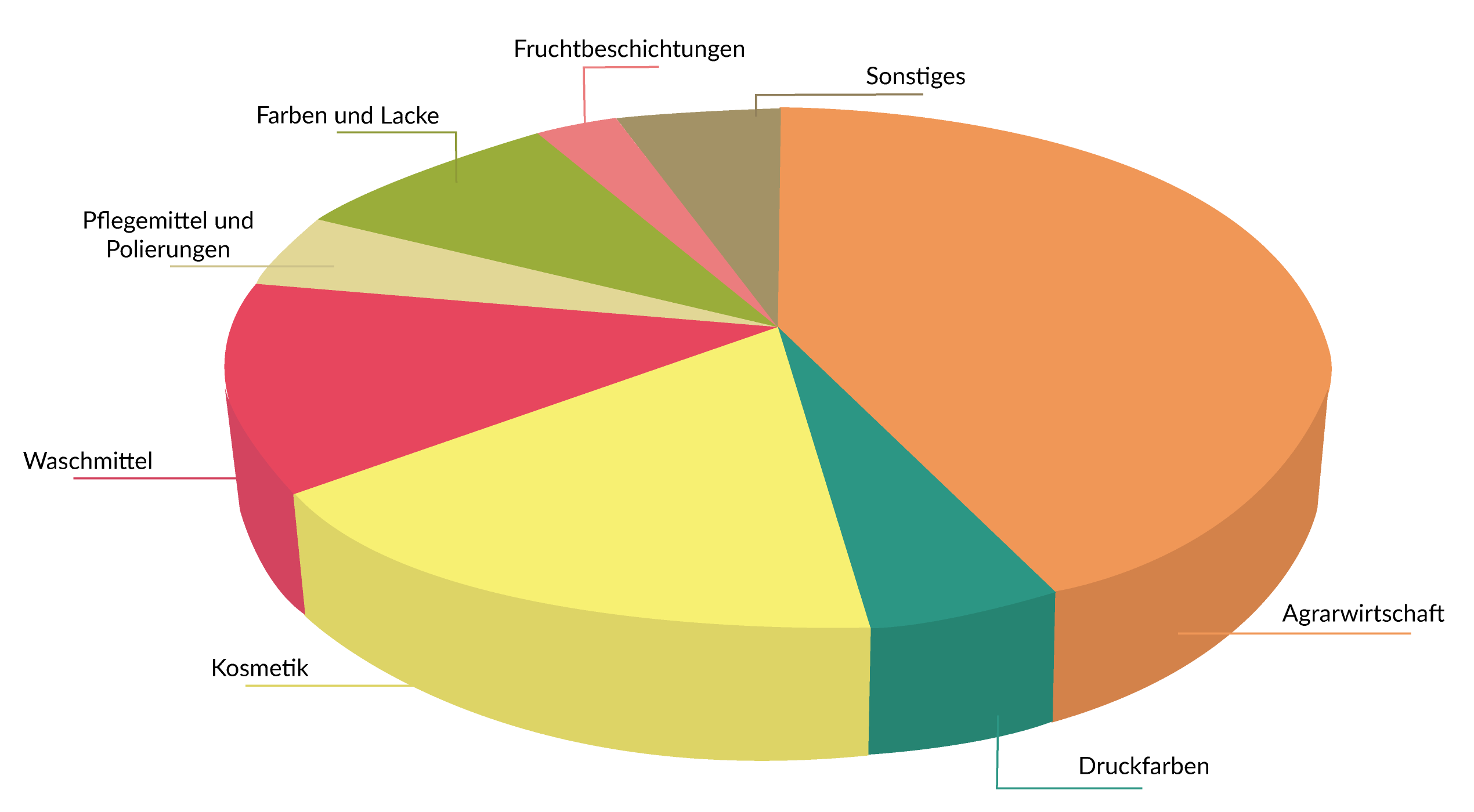

For the reduction of consciously/directly used microplastics (TYPE A)

Agriculture

Microplastics released annually (EU): 23,500 t/a (ECHA S.74)

The world's largest share of deliberately and directly released primary microplastics is caused by the agricultural sector through plastic in fertilisers and pesticides.

Mikroplastik wird in sogenannten „controlled-release-Formulierungen“ (CRF) eingesetzt um folgende Eigenschaften zu erreichen: Kontrollierte Freisetzung von Nährstoffen über einen Zeitraum von bis zu 18 Monaten durch Mikroverkapselung Anti-Caking-, Prilling- und andere konservierende Funktionen;

As a fertiliser additive to reduce dust formation;

When applying fertiliser to reduce fertiliser run-off.

Similar to microencapsulation, seed coating involves the deposition of polymeric material on the seed, so that coated seeds are nothing more than microplastic particles released directly into the environment. Often the aim is to protect the seed from early decomposition and to reduce dust formation and runoff.

By using BIOMERE, these properties can be achieved without harming the environment. The period of biodegradability is decided by you, acting within the framework of the EU Fertiliser Regulation (2019/1009) and for the benefit of the environment. BIOMERE only degrades when exposed to the aquatic environment, i.e. rain or irrigation.

Cosmetics

Microplastics released annually (EU): 9300 t/a (ECHA S.74)

Microplastics are used in cosmetic products to perform a variety of functions: For use as an exfoliating or cleansing function in wash-off cosmetics to remove dirt, clogged pores, or dead skin cells (e.g., scrubs, face washes, toothpaste). In addition, microplastics are used in products intended to be removed after use (e.g., conditioners (except leave-in), hair dyes, conditioning masks, etc., as well as shampoos, soaps, etc. (except those with an exfoliating/cleaning function). Also in products intended for prolonged contact with the skin, hair or mucous membranes (e.g. skin care, make-up, lipstick & lip care, deodorants, sun & self-tanning products, hair care & styling products, etc.).

There is a checklist from the NGO BUND that can be used to identify which cosmetics use microplastics.

There are alternatives to polymer additives. BIOMERE guarantee the highest quality without harming the environment.

Contact us and and get advice on this topic.

Printing Inks

Microplastics released annually (EU): approx. 2700 t/a (ECHA S. 74)

There is a wide range of printing ink products for which BIOMERE is used as a plastic-free substitute: Printing toner (laser printers, offset printing inks (oily), flexo printing inks (aqueous and solvent), gravure printing inks (solvent), UV drying systems, etc.

BIOMERS provide improved abrasion and scratch properties, UV. and water resistance, as well as gloss, matting effects and improved haptics.

Printer toner in laser printing: An electrostatic digital printing process that uses powdered ink (toner) to transfer an image onto paper. The toner is then heated to permanently fuse the text to the paper. Generally, the toner is provided in a toner cartridge. The toner is usually made of plastic granules of, for example, polypropylene (PP), fumed silica and various minerals to make the powder electrostatic. The special polymer used may also be based on styrene-acrylate copolymers, polyester resins, styrene-butadiene copolymers or some other special polymers. The formulation, granule size and resulting melting point vary.

The particle size is typically around 10 µm. Toners are evolving towards smaller granule sizes through the application of new technologies, such as emulsion aggregation. Emission of microplastics is expected to occur primarily during press maintenance. It is estimated that on average 3% of the toner in each cartridge can be released.

Regardless, using plastic-free and biodegradable BIOMERE is the more sustainable choice.

Contact us and and get advice on this topic.

Paints and Varnishes

Microplastics released annually (EU): min. 5200 t/a (ECHA S. 74)

Microplastics are an integral part of polymer dispersion binders in waterborne paints and coatings, where they contribute to a film-forming function. Microplastics are also used as a special additive in architectural and industrial coatings (wood, plastic, metal). Microplastic additives improve properties such as matting, abrasion resistance, durability, scratch resistance, marking resistance and side gloss control. In addition, they are used to add texture and structure to surfaces. Microplastics are also used in combination with metallic pigments to create a glitter effect.

The release of microplastics into the environment occurs mainly through the cleaning of paint shops and the improper disposal of waste, but also through erosion and weathering.

BIOMERE perform the same as conventional waxes without unnecessarily polluting the environment.

Contact us and and get advice on this topic.

Detergents and Cleaning Agents

Microplastics released annually (EU): 9700 t/a (ECHA S. 74)

Microplastics are used in cleaning and maintenance products to perform a number of functions, including as abrasives, odor carriers, opacifiers and anti-foaming agents. They can be used in surface cleaning products, fabric softeners, dishwashing products.

ECHA has granted the industry a transition period until 2027. After that, conventional additive polymers will be banned.

Wechseln Sie bereits jetzt auf bestehende nachhaltige Lösungen. Mit BIOMERE leisten ihre Produkte das Gleiche wie Sie es gewöhnt sind – und zwar ohne dabei die Umwelt zu belasten.

Contact us and and get advice on this topic.

Care Products and Pollitures

Microplastics released annually (EU): <2430 ta (ECHA)

Microplastics are used in personal care products and pollitures to perform a number of functions, including as abrasives, odor carriers, opacifiers and antifoams. They are used in many personal care products, such as:

Shoe care, furniture care, car care, car wash (care products), floor care, leather care, waxes and pollitures.

BIOMERE guarantee functions such as surface protection, water protection, gloss and matting, lubricant, polishability, resistance (UV, water, chemicals)

ECHA has granted this industry a transition period until 2027. After that, conventional additive polymers will be banned for these applications.

Wechseln Sie bereits jetzt auf bestehende nachhaltige Lösungen. Mit BIOMERE leisten ihre Produkte das Gleiche wie Sie es gewöhnt sind – und zwar ohne dabei die Umwelt zu belasten.

Contact us and and get advice on this topic.

Coating of fruits (e.g. citrus fruits)

Lemons, oranges, limes, pomelos, grapefruits, tangerines and many other fruits are not only coated with insecticides, fungicides and the like, but in the end they are also coated with PE wax. This coating is necessary to protect the fruit from drying out and rotting. This way the fruits stay fresh until they reach us in the supermarket. We know these fruits for example under the name "waxed". After consumption, these PE waxes often end up in the environment, representing another source of primary microplastics.

BIOMERs are ideal for protecting fruit and keeping it fresh. With BIOMER 60 we even have a specially approved wax for food contact, which quickly biodegrades in the aquatic environment. Switch to the sustainable and economical substitute to PE waxes now!

Contact us and and get advice on this topic.

Other

Pharmaceuticals

In pharmaceuticals for human and veterinary medicine, microplastics are mainly used for their controlled release (CR) and taste masking functions mainly in solid dosage form (tablets and capsules), but also in parenteral and inhalation drug formulation (microencapsulation).

In addition, microplastics can be used as binders, disintegrants, diluents, lubricants (only in solid dosage forms). Microplastics are classified in the EU Pharma Code as either excipients or API (Active Product Ingredient). In addition, controlled release formulations are commonly used to extend patent protection and market life of drugs (+5 years).

In pharmaceuticals, microplastics form the backbone of many "controlled release" drugs: unlike immediate release, these formulations can deliver drugs with a delay after administration (delayed release) or over a longer period of time (extended release) or to a specific target organ in the body (targeted release dosage). Controlled release mechanisms allow the agent to be protected from the physiological environment (e.g., enzymes, pH) to control its release at a specific, predetermined rate to a specific site/organ. In addition, microplastics can be used for their taste-masking function. In pharmaceuticals, microplastics are often classified as excipients, but can also be approved as active pharmaceutical ingredients (APIs).

Food Supplements

Dietary supplements include vitamins, minerals, botanicals, amino acids, enzymes and many other products.

In this sector, microplastics appear to be used essentially for their controlled release (CR) and taste masking functions with a film-forming function.

Some microplastics are approved as food additives for use in solid food supplements under EU Regulation (1333/2008).

Oil and Gas Industry

Microplastics are used in cement/cement additives, viscosifiers, lost circulation materials, drilling lubricants, defoamers, fluid loss control chemicals, asphaltene inhibitors, friction reducers and other drilling, production or pipeline applications

Adhesives

The intentionally added microplastic can be used as a spacer in adhesives, and metal-coated microplastic particles can be used in conductive adhesives in electronics.

Medium for Blasting / High Pressure Cleaning

Plastic granules are used to remove difficult contaminants such as paint, plastics, rubber, and adhesives from plastic tools and molds, etc. The underlying surface is usually not affected by blasting, as the various plastic materials are somewhat softer than those made of minerals or metal. The material of the granules varies according to the desired properties; it can be poly-methyl-metacryl polymer, melamine, urea-formaldehyde, urea-aminopolymers or polyamino-nylon type. The granule size ranges from 0.15-2.5 mm and the relative density is > 1000 kg/m3, which means they do not float.

3D - Printing

Microplastics released annually (EU): not known t/a (ECHA, p. 74)

Polymer materials are used in consumer fused deposition modeling (FDM) printers. These printers are smaller than industrial printers and can be purchased by private consumers to print smaller objects.

The toner in conventional laser printing is usually made of granulated plastic to make the powder electrostatic.

Contact us and and get advice on this topic.

Biomere

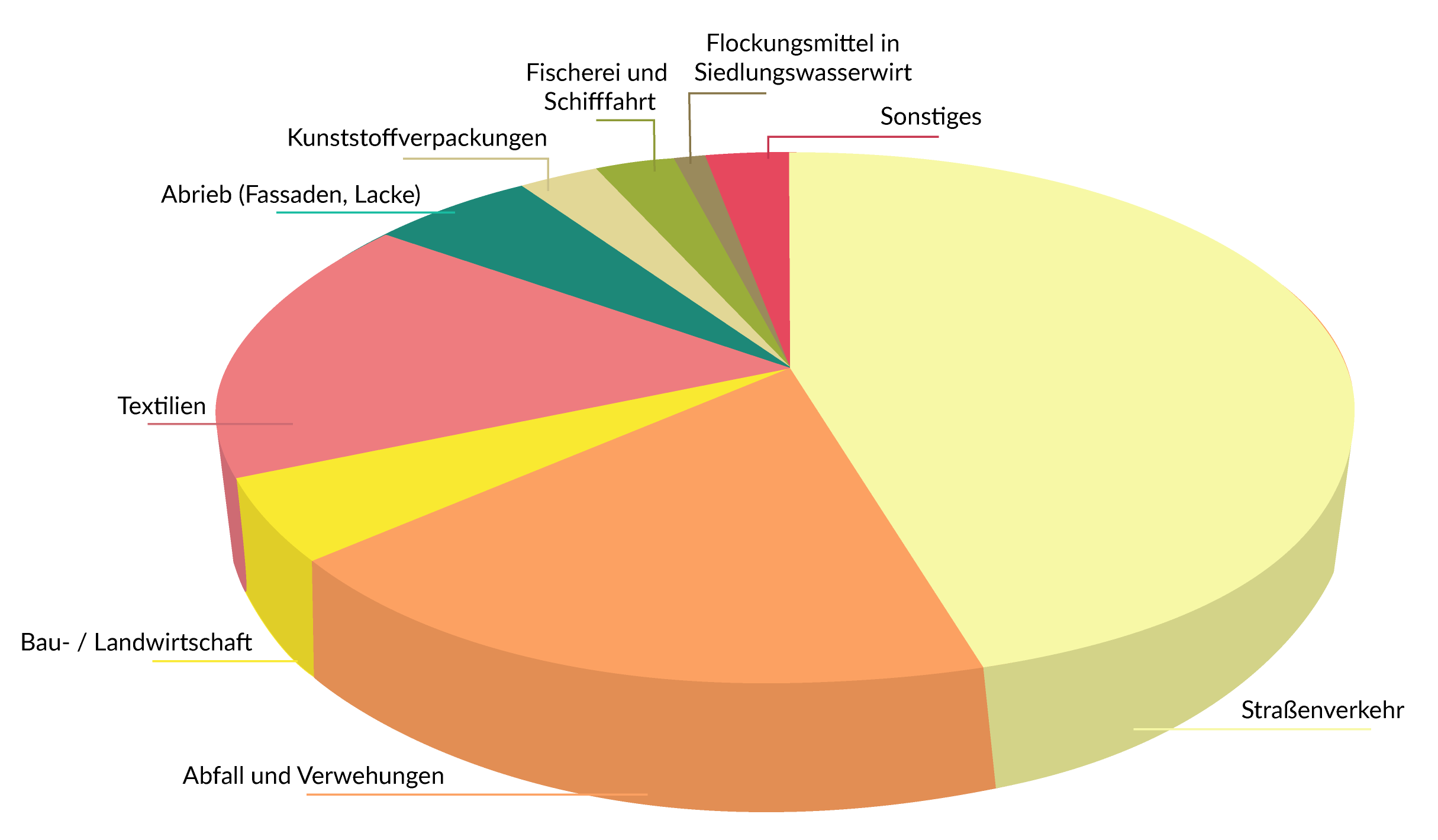

For the reduction of consciously/directly used microplastics (TYPE B)

Road Traffic

Every year, 1.2 kilograms of microplastic per capita are released into the environment by road traffic. This is caused by tire abrasion from cars, trucks, motorcycles and bicycles. But also the abrasion of bitumen in asphalt contributes to the amount of microplastic. According to a study by the Fraunhofer Institute for Environmental, Safety and Energy Technology in Germany alone, a total of around 446,000 tons of plastic are introduced into the environment each year in 2018, 330,000 tons of which are microplastics. The majority of this comes from the abrasion of car tires and brakes and accounts for about one-third. In addition, the Alfred Wegener Institute found the highest microplastic levels in snow in samples taken from a rural road in Bavaria - the concentration was 154,000 particles per liter.

The microplastic particles are distributed both in the atmosphere and in the water cycle. For example, around 48,000 tons of microplastics end up in the Arctic and 140,000 tons in the world's oceans every year. To limit transport via the water cycle, areas of road construction and street cleaning must be improved. "Microplastics that have already been created must be collected as best as possible through cleaning and filtering technology. In addition, we need road surfaces that minimize abrasion or better retain or filter the abrasion particles," Nadja Ziebarth, microplastics expert at the Bund für Umwelt und Naturschutz Deutschland (BUND).

In any case, it's more sustainable to switch to plastic-free biomers from the start.

Learn more:

Waste and Drifts

On average, about 5.4 kilograms of microplastics are released per capita per year in Germany. This was determined by researchers at the Fraunhofer Institute for Environmental, Safety and Energy Technology (UMSICHT) as part of the study "Plastics in the Environment: Micro - and Macroplastics". This amount corresponds to a plastic quantity of more than 800 water bottles.

Many emissions are predominantly generated in the recycling process during waste disposal and thus waste disposal also represents the third largest polluter with 303 grams. In addition, there is the impact of non-degradable plastic that accidentally ends up in the compost. The origins of this microplastic are both private households and supermarkets. For example, one ton of compost from private households contains up to 440,000 microplastic particles. In supermarkets, spoiled food is often shredded directly with the packaging, as it would be too costly and unprofitable to unpack the food, and automated removal is not sufficiently accurate. The municipal utility then receives the waste and mixes it with the sewage sludge as biomass. The sewage sludge is then used in agriculture as fertilizer, and this is how the microplatic particles eventually end up in the soil.

Drifting on sports fields and playgrounds with artificial turf releases an average of 132 grams of microplastics annually. The annual consumption of plastic packaging causes 99 grams of microplastic.

In any case, it's more sustainable to switch to plastic-free biomers from the start.

More info on these topics:

Textile

Microplastics released annually (EU): approx. 46,175 t/a (ECHA)

Plastic clothing, especially fleece, releases fibers made from polyethylene, polyamide, polyester and similar materials into the wastewater with every wash cycle. The same applies to recycled textiles made of synthetic fibers. The proportion of abrasive fibers is further increased by the addition of fabric softener (study by the University of Plymouth 2016). Waxes and polymers are also used in the manufacture of textiles. Thus, this improves the processability of the fibers. Microplastics are also released with the printing of textiles.

Biomere schaffen eine nachhaltige und funktionale Abhilfe für dieses Problem. So sorgen Biomere für eine hydrophobierende Oberflächeneigenschaft der Textilien und verbessert die Schneidfähigkeit des Produkts oder die Robustheit der Fasern. BIOMERE eigenen sich hervorragend für das sogenannte „Finishing“ von Textilien, sowohl bei natürlichen als auch synthetischen Gewebe. Eine weitere naheliegende Anwendung sind Geotextilien. Herkömmliche Plastikadditive werden zusammen mit synthetischen Fasern aus den Textilien abgewaschen und gelangen somit direkt in die Umwelt. Bei Geotextilien versickert Plastik über die Zeit direkt in die Böden.

More info here:

Construction Sites and Agricultural Products

Microplastics released annually (EU): not known

Primary type B microplastics are increasingly used in reinforced concrete, such as polymer fiber-reinforced concrete or polymer-modified concrete instead of conventional steel "rebars." These reinforcing bars, rods or grids are incorporated into the concrete to increase its tensile strength. Fibers made from microplastics are cheaper, lighter and safer to handle than steel. They also give concrete many positive properties and make it corrosion and fire resistant by preventing spalling.

In addition, primary microplastic type B is also used as a filler in concrete/cement. In this context, it is used on the one hand as a means of disposing of/recycling plastic waste and on the other hand as a partial substitute for conventional aggregates. It is assumed that the polymers used, microplastics consist of shredded and/or ground used tires or plastic pallets. Other applications include wall and floor tile adhesives to increase adhesion, flexibility and grip. It is assumed that the release of microplastics occurs mainly through spills during productions or on the construction site.

"Tools should be thoroughly cleaned in water immediately after use to remove excess material," this is stated in the instructions for use for polymer-modified wall and floor tile adhesives and is intended to mitigate release into municipal wastewater systems. There are also warnings against disposing of excess cement or adhesive. However, there is no research at this time as to what the actual release is.

Primary microplastics type B are also used in agriculture in so-called geotextiles. Microplastics have been detected on agricultural land, as well as in fertilizers and compost. Through atmospheric transport, the small particles also reach remote places on earth (e.g. Arctic lake ice, Alpine glaciers. In any case, it is more sustainable to switch to plastic-free biomers from the outset.

Abrasion of Facades and Paintwork

Paints and varnishes are a source of microplastics, as the binders consist mainly of plastics. These are used as thickeners or to increase resistance. Plastic particles are added to paints, for example in the form of acrylic polymers, polyamide or polyacrylonitrile. Building paints are used for walls and ceilings, and paint particles found in the environment also come from marine paints and facades as well as road markings.

Biomers are a perfect substitute for the polymers in paints and coatings, as they can provide the same scratch resistance and UV resistance, and are also biodegradable.

Learn more:

Fishing and Maritime

Ghost nets, abandoned fishing nets, become a danger to marine life because they continue to fish indefinitely or lie at the bottom of the ocean and slowly disintegrate into tiny plastic fibers. This contributes to microplastic pollution in the oceans. Ghost nets can enter the oceans through boating accidents, storms or improper disposal.

Derzeit werden Schiffsanstriche als Quelle für Mikroplastik in den Meeren unterschätzt. Eine Studie der Universität Oldenburg stellt fest, dass Mikropartikel in der südlichen Nordsee überwiegend aus Farben und Lacken stammen. „Wir nehmen an, dass Schiffe im Wasser eine Art ‚Bremsspur‘ hinterlassen, die als Quelle von Mikroplastik eine ähnlich große Bedeutung hat wie der Reifenabrieb von Autos an Land“, so die Forscherin.

BIOMERE can solve this problem because they can be added to coatings instead of polymers. They have the same properties and are biodegradable in water.

More Info here:

Plastic Packaging

Another input pathway of secondary microplastics is the release of plastic products. On the one hand, these are used plastic articles released into the environment in an uncontrolled manner, which enter inland waters and oceans directly or with wind, rain and surface water. On the other hand, plastic products are intentionally released (garbage dumping, fishing nets, cultivation foils from agricultural areas, fertilizers), which decompose under the prevailing physical and chemical influences.

Microplastics are used as specialty additives in thermoplastic masterbatches and engineering materials as light diffusion agents, anti-blocking agents and to introduce a desired surface texture. Pre-production plastic (resin) granules (also called "nurdles") used as raw material in extrusion / molding processes in article production are also microplastics due to their size.

BIOMERE können einen wichtigen Beitrag bei der Herstellung und Beschichtung von Kunststoffverpackung leisten.

BIOMERE are already being used successfully in the production of BIO plastics.

Some BIOMERE also have food contact approval.

More Info here:

Sontiges - Papier

Paper Manufacturing:

During papermaking, the pulps, or more precisely the pulp suspensions, come into contact in particular with the wires, which are largely made of polyesters or polyamides and exhibit high abrasion behavior. Other important equipment parts of the paper machine are conveyor belts, seals and storage bins, which also come into contact with the pulps. However, there is no published data on the fate of abrasion particles and their size composition. In addition, dispersion plastics are used in the production and processing of paper. These impart different properties or finishes to paper for graphic paper applications. If papers are used in the packaging industry, they often contain synthetic polymers; these are, for example, plastic coatings, components of adhesives and printing inks. Packaging papers are here to stay, and in 2018 they accounted for around 53% of annual paper production. In Germany alone, a total of around 7.5 million tons of packaging papers are consumed annually. The polymer content in most products is less than 5%, which makes it possible to recycle this paper as waste paper. It is also unclear to what extent microplastics are produced during composting or during the biodegradation of papers containing polymers. Currently, no information is known about standardized analytical methods for paper products, the degradation of paper products under industrial composting conditions or legal regulations for papers. The Research Institute Paper Technology Foundation (PTS) and the Department of Paper Manufacturing and Mechanical Process Engineering (PMV) at the Technical University of Darmstadt are researching the transfer of methods from other fields for the paper industry and the development of a database.

Learn more: